HOW WE DO IT

The steps outlined below illustrate our approach to implementing MMC and DfMA

Architrcture Plan

Architectural Plan

Initiates the process by receiving architectural plans from the client, outlining the structure's design and requirements.

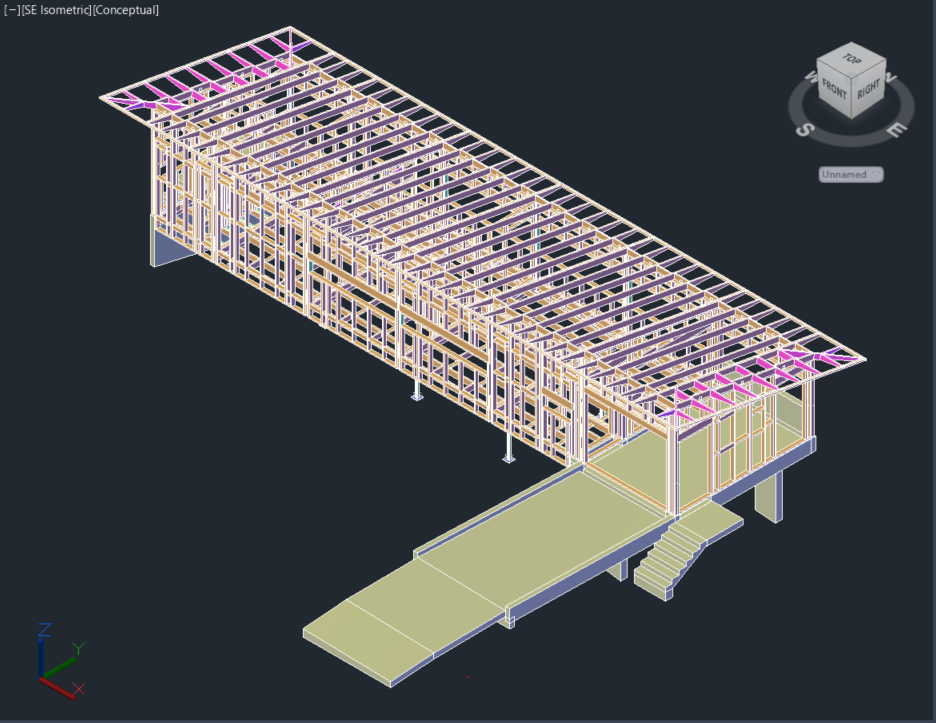

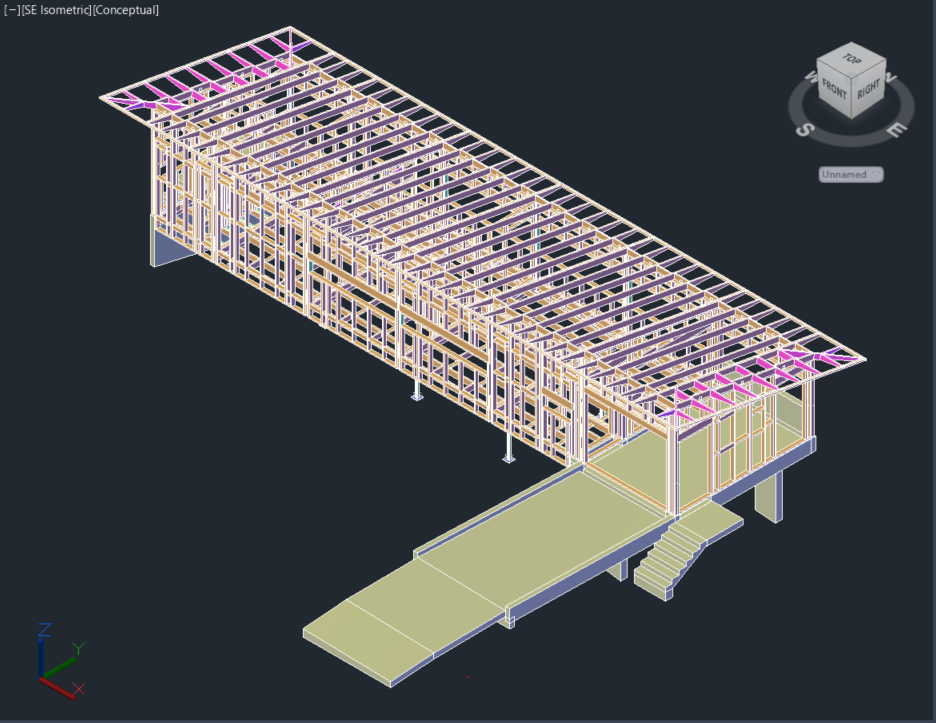

Digital Model

Building a detailed 3D model using HSBCAD software, accurately representing the structures components and their geometry.

Shop Drawing

Shop drawings are created to guide the fabrication process in the factory, ensuring precise dimensions for uneven-shaped timber components.

Closed Panel Timber Frame xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx

IFC

Generates Industry Foundation Classes (IFC) files from the model, providing a standardized format for sharing 3D object data across different software platforms.

Machine File

Each timber component is assigned it own unique identified (posnum) and can then be processed by state of the art automated machinery to ‘deliver’ precision products to the factory

Machine File

Utilized for collaborative design review and coordination among project stakeholders, enhancing communication and decision-making.

Involves the assembly of structural frames and installation of exterior cladding materials, shaping the building's envelope.

Framing and Sheeting

Automation in DfMA streamlines design and production, reducing errors and speeding up processes through advanced digital tools and systems.

Automation

Assembly Stage

Incorporates prefabricated components during on-site assembly, optimizing construction efficiency and reducing build time.

Finished Building

Represents the successful completion of the DfMA process, delivering a high-quality, sustainable structure that meets client expectations and regulatory standards.